About us

MINH KHAI TEXTILE Import-Export Joint Stock Company

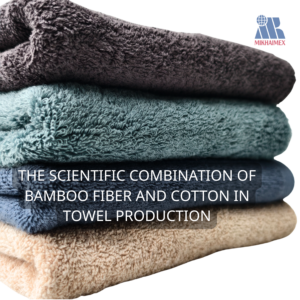

Minh Khai Textile (Mikhaimex) is one of the leading units of Hanoi industry. The company was established in the 1960s to produce and meet the demand for facial towels and cotton towels for the domestic and export markets. Especially markets like Japan, Korea, US, EU…

After nearly 50 years of production and market development, our company is proud to be a pioneer enterprise in the field of textiles and garments, producing face towels, cotton towels, bath towels, hand towels… for export with high quality. High quality, the company’s products are manufactured on modern industrial equipment systems, meeting strict requirements on ENVIRONMENTAL PROTECTION from Europe. Now the company has been reaping many successes and has become a leading enterprise in Vietnam with a strong brand in the textile and garment field.

Readmore

Hotel towel

Family Towel

Kid Towels

Fiber types

COTTON

COTTON ORGANIC

TENCEL

MODAL

BAMBOO

SOYBEAN

Our Factory

A cotton spinning factory typically begins its operations with the procurement of raw cotton, sourced from cotton farms across the globe. The quality of the raw material is paramount, as it directly impacts the quality of the final product. Our factory imports raw cotton from renowned sources in India and Pakistan, regions known for their high-quality cotton crops.

Once the raw cotton arrives at the factory, it undergoes a series of meticulous processes to convert it into yarn, the fundamental building block of textile production. The first step in the spinning process is the cleaning and carding of the raw cotton fibers to remove impurities and align them in a uniform direction. Next, the fibers are drawn and twisted into thin strands, known as roving, which are further attenuated and twisted to form yarn of varying thickness and strength. These yarns are then wound onto spools or cones, ready to be used in weaving or knitting machines to create fabrics and textiles.

Modern cotton spinning factories are equipped with state-of-the-art machinery and technology to ensure efficiency, precision, and consistency in the spinning process. Automated systems monitor and control various parameters such as tension, twist, and yarn diameter to maintain the desired quality standards.

Furthermore, our factory boasts an impressive production capacity of 500 tons per month, demonstrating our commitment to meeting the demands of the market while maintaining the highest standards of quality and efficiency.

At our factory, we specialize in the art of weaving premium cotton fibers into luxurious towels that embody comfort, durability, and style. From the moment raw cotton enters our facility, it embarks on a journey of transformation guided by precision and expertise.

With a keen eye for quality, we meticulously clean, card, and spin the raw cotton fibers to create yarns of unparalleled softness and absorbency. These yarns are then skillfully woven on our state-of-the-art looms, where they take shape as a diverse range of towel styles and designs.

Despite our high production volume, we never compromise on quality. Each towel undergoes rigorous quality control checks to ensure it meets our stringent standards for softness, durability, and colorfastness. Our commitment to excellence is reflected in every towel that bears the hallmark of our factory.

Moreover, sustainability lies at the heart of our operations. We implement eco-friendly practices and technologies to minimize waste and conserve resources, ensuring that our production process is as environmentally responsible as it is efficient.

In conclusion, our cotton towel weaving factory is a testament to our dedication to craftsmanship, quality, and sustainability. With a production capacity of 300 tons per month, we continue to set the standard for excellence in the textile industry, one luxurious towel at a time.

At Minh Khai, we understand the importance of color and design in creating towels that captivate the senses and elevate the bathing experience. Our dyeing facility is equipped with state-of-the-art technology and operated by skilled technicians who specialize in the art of color application.

From rich, deep hues to subtle pastels, our dyeing process is meticulously tailored to bring out the best in each towel. We utilize eco-friendly dyeing techniques and premium quality dyes to ensure that our towels retain their vibrancy wash after wash, without compromising on environmental responsibility.

In addition to dyeing, our facility also offers a range of finishing services to enhance the look and feel of our towels. From softening treatments to specialty finishes, we tailor each towel to meet the unique preferences of our customers, ensuring a truly personalized experience.

But our commitment to excellence extends beyond the aesthetic. We prioritize sustainability in every aspect of our operations, from water and energy conservation to waste reduction and recycling. By implementing eco-friendly practices, we strive to minimize our environmental footprint while delivering towels of the highest quality.

Modern factory

The factory meets ISO standards, with modern machinery and equipment

Production capacity

Produce large quantities according to customer requirements, to meet export requirements

European standard products

Export quality standards, meeting the requirements of the most demanding markets